Redefining environmental material: the ‘invisible guardian’ of sewage system.

✅ World's First Dual Certification: INDA/EDANA Dual Standard Dissipative Certification

✅ Zero Microplastic Residue: Hydrotesting

✅ Cost-saving expert: 40% less energy consumption than traditional PP non-woven processing.

Revolutionary applications in three industries

🔹 Personal Care:

Flushable sanitary napkin backing/disposable liner, no risk of clogging for toilet flushing

🔹 Medical Consumables:

Post-operative care pads + flushing catheter set, sewage system compatibility

🔹 Pet Economy:

Litter pads/pet wipes substrate, flushed and dispersed to work synergistically with bio-enzymatically broken down cat litter

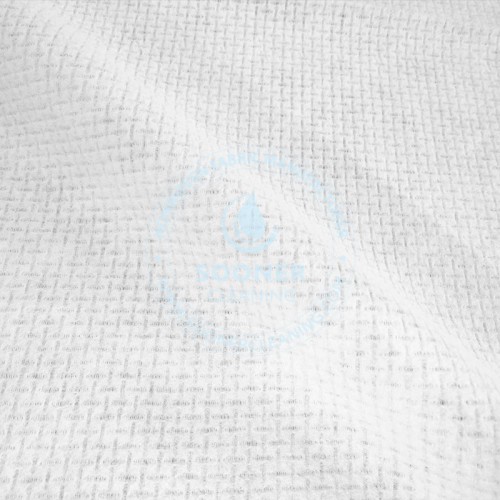

Core process black technology

1️⃣ Gradient Hydroentanglement Technology:

5 groups of high-pressure water needles entangled layer by layer, dry strength to maintain the use of demand, the fibre bond automatically breaks in contact with water

2️⃣ Intelligent degradation regulation:

Customised wood pulp/viscose ratio (30%-70%), precise control of decomposition speed in different scenarios.

3️⃣ Nano anti-mould layer:

Plant extracted antimicrobial agent embedded in fibre, storage period extended to 24 months without yellowing

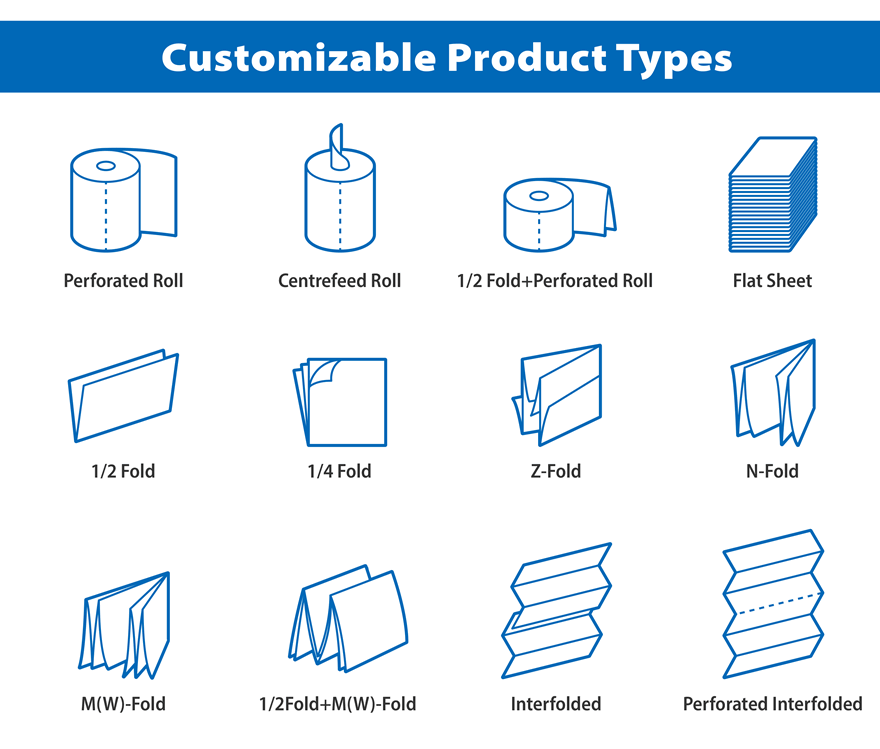

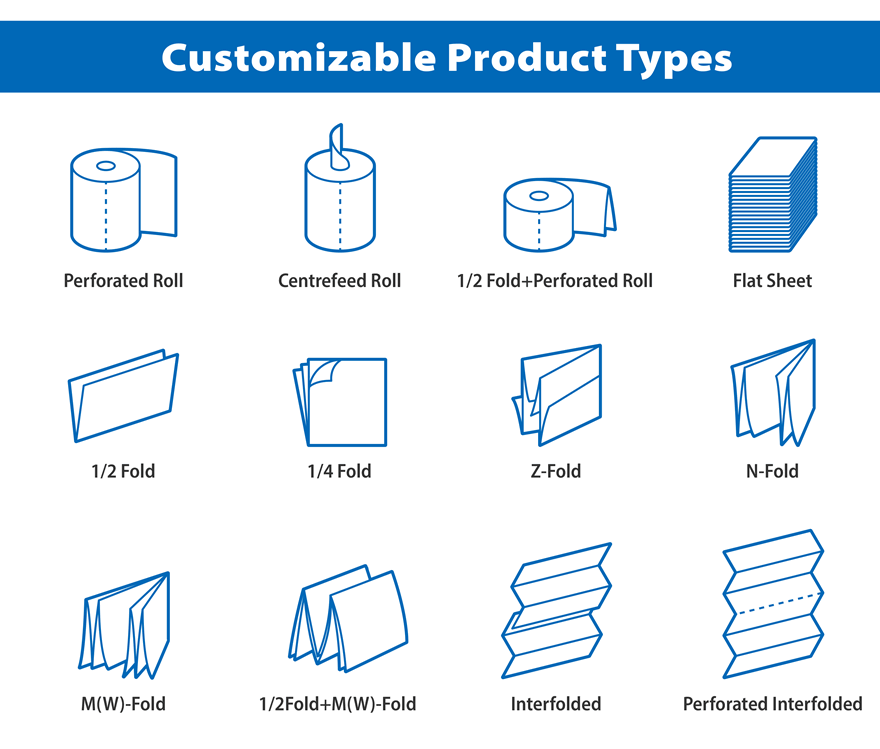

Enterprise customised solutions

Grammage selection: customisable

Customised width: customisable, suitable for fully automated production line.

Co-operation rights and benefits: free dispersible samples