Wet Wipe Raw Material As wet wipe factories enter their peak stockpiling period toward year-end, bulk procurement demand is rapidly increasing. Export-oriented factories targeting markets in Europe, the Middle East, and Southeast Asia face particularly concentrated orders, tight deadlines, and stringent delivery requirements. How to select a reliable Spunlace Nonwoven supplier? How to plan the supply cycle? Will year-end procurement prices increase? This article provides practical guidance for factory procurement managers, covering supply cycles, delivery stability, price fluctuations, and supplier selection criteria.

I. Why is year-end a critical period for bulk purchasing wet wipe raw materials?

1. Concentrated overseas market demand

Pre-stocking for Christmas, New Year, back-to-school season, and Chinese New Year

Bulk orders from major retailers and brands

Distinctive production and delivery peaks for export-oriented factories

2. Rising raw material costs

Year-end typically sees:

Fluctuations in fibre raw materials (viscose, polyester)

Increased sea freight rates and tight container availability

Rising factory labour and logistics expenses

Factories are advised to place orders 1-2 months in advance to lock in prices and delivery dates.

II. Three Critical Metrics for Bulk Wipe Material Procurement

Core Metric

|

Procurement Impact

|

Assessment Method

|

Raw Material Stability

|

Product Quality

|

Absorbency - Water Absorption Ratio Test

|

Supply Cycle

|

Timely Delivery

|

Monthly Production Capacity, Production Cycle, Delivery Commitment

|

Certification Completeness

|

Export Eligibility

|

SGS, MSDS, ISO, FDA, REACH

|

III. Year-End Supply Cycle Reference for Wet Wipe Materials

Conventional spunlace nonwoven fabrics offer rapid delivery within standard production cycles, suitable for continuous bulk supply. However, year-end peak season typically extends lead times due to concentrated orders and heightened logistics pressure.

Stable delivery cycles.

High technical requirements and complex processes necessitate advance production scheduling to secure manufacturing capacity.

Procurement Recommendations:

Prior to the year-end peak season, plan procurement cycles in advance. Select suppliers with sufficient monthly production capacity, extensive export experience, and comprehensive certifications to effectively safeguard delivery timelines.

IV. How to Assess Reasonableness of Year-End Bulk Purchase Prices?

The reasonableness of year-end wipe material pricing primarily depends on the following influencing factors:

Influencing Factor

|

Controllability Description

|

Non-woven fabric raw materials (viscose/polyester, etc.)

|

Susceptible to raw material market fluctuations

|

Processing costs (printing, cutting, packaging, etc.)

|

Negotiable items; stabilise costs through consistent partnerships

|

Sea freight, international delivery, and container availability

|

Typically uncontrollable, particularly sensitive during peak seasons

|

SGS, MSDS, ISO, and other certifications

|

Can be prepared in advance; selecting suppliers with existing certifications reduces costs

|

Procurement Recommendations: Select factories with stable supply capacity and existing certifications to effectively avoid additional costs

V. How to Assess Whether a Spunlace Nonwoven Supplier is Suitable for Long-Term Collaboration?

✔ Possesses stable monthly production capacity (>1500 tonnes/month)

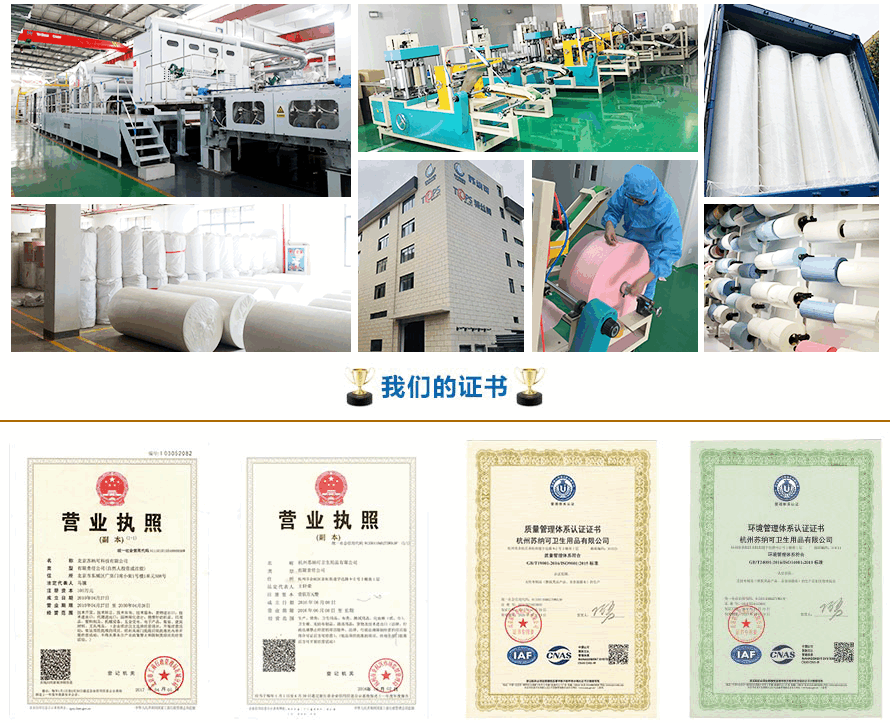

✔ Possession of essential export certifications (SGS/MSDS/ISO/ROHS/FDA)

✔ Capability for customisation (grammage, width, colour, mesh pattern)

✔ Proven export experience (Europe, Middle East, USA)

✔ Consistent delivery schedules, including peak season fulfilment

VI. Year-End Procurement Recommendations: How to Avoid Delivery Delays and Stockouts?

Risk

|

Solution

|

Raw material shortages

|

Sign supply agreements with factories to secure quotas in advance

|

Sea freight delays

|

Prioritise trade terms like FOB or EXW; book shipping space early

|

Unstable delivery times

|

Select suppliers with higher and more consistent production capacity

|

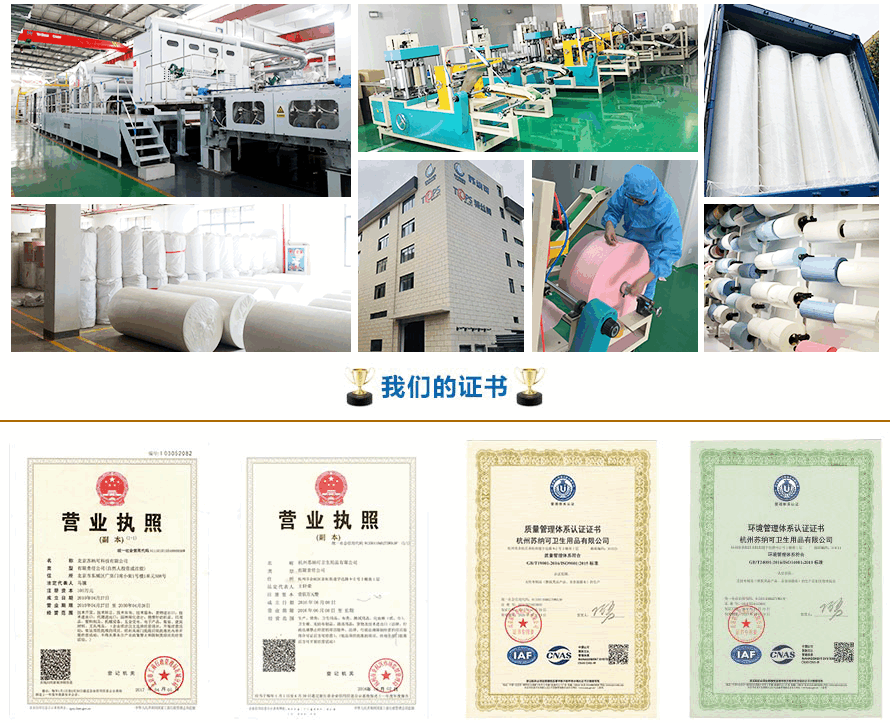

VII. How does Soonercleaning ensure supply for year-end bulk procurement?

As a specialist Chinese supplier of wet wipe raw materials, Soonercleaning possesses:

✔ 11 spunlace production lines with monthly capacity exceeding 5,000 tonnes;

✔ Comprehensive export certifications including SGS, MSDS, ISO, REACH, and FDA;

✔ Stable delivery schedules;

✔ Support for OEM/ODM, custom printing, logo packaging, GSM specifications, etc.;

✔ Long-term partnerships with European, American, Japanese, and Middle Eastern clients, backed by extensive export experience;

Soonercleaning facilitates customisation for rolls, finished products (printed, medical-grade, flushable materials, wood pulp cloth, etc.).

Conclusion: When is the optimal time for year-end bulk procurement?

Optimal procurement window: Late October – Mid-December

Should you be planning year-end or Q1 2026 wipes material procurement, securing supply earlier yields greater advantages.

Request quotations / Sample dispatch / Delivery schedule proposals