1. What Is Spunlace Nonwoven Fabric and How Is It Made?

Spunlace nonwoven fabric is one of the most widely used nonwoven materials in today’s market. Known for its soft texture, excellent strength, and lint-free performance, it is commonly used in personal care, medical, and industrial cleaning products. But what exactly is spunlace nonwoven fabric, and how is it made?

2. What Is Spunlace Nonwoven Fabric?

Spunlace nonwoven fabric, also known as hydroentangled nonwoven, is a fabric made by entangling fibers with high-pressure water jets. Unlike woven textiles, it doesn’t require yarns or weaving processes. The fibers are mechanically bonded through water pressure, creating a uniform and flexible structure without any chemical binders.

3. How Is Spunlace Nonwoven Fabric Made?

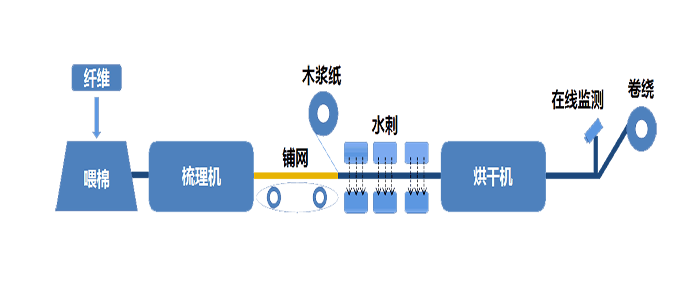

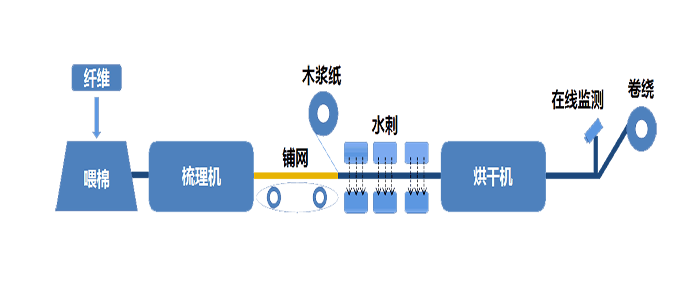

The complete production process of spunlace nonwoven fabric typically includes the following steps:

Fiber Feeding – Different types of fibers such as viscose, polyester (PET), or wood pulp are blended and fed into the machine according to the required ratio.

Opening – A high-power air blower separates and loosens the fiber clusters, ensuring the fibers become fluffy and evenly dispersed.

Carding – The opened fibers are combed into a thin, uniform fiber web composed of single fibers, preparing them for web laying.

Web Laying – The fiber web moves back and forth on a conveyor to form layers. There are three common laying methods: parallel, cross, and random web laying, each offering different texture and strength characteristics.

Hydroentanglement (Spunlacing) – High-pressure water jets strike the web, causing the fibers to move, interlace, and entangle with each other, forming a strong, cohesive nonwoven structure.

Drying – The web is dried to remove moisture and volatile substances, stabilizing the fabric’s surface.

Winding – The finished spunlace nonwoven fabric is rolled into large rolls for further processing or packaging.

4. Key Features of Spunlace Nonwoven Fabric

Soft and skin-friendly

High tensile strength

Lint-free and clean surface

Chemical-free bonding

Biodegradable fiber options

These properties make spunlace nonwoven fabric a preferred choice for both disposable and reusable applications.

5. Applications

Spunlace nonwoven fabric is used across a wide range of industries, including:

Personal Care: wet wipes, facial masks, cosmetic pads

Medical & Healthcare: surgical gowns, drapes, disinfectant wipes

Industrial Cleaning: high-strength wiping cloths, electronic wipes

Household Use: kitchen wipes, disposable towels, and mop cloths

Its combination of softness, strength, and eco-friendly performance meets the needs of modern consumers and professional users alike.

5.The Development Prospects Of Spunlace Nonwoven Fabrics www.soonercleaning.com

With the growing global emphasis on environmental protection and sustainable development, biodegradable materials have become one of the main directions for the future development of spunlace nonwoven fabrics.