With the widespread application of non-woven fabric in the medical, clothing, and home furnishing industries, more and more people are paying attention to a key question: **Is non-woven fabric breathable?** This article will take an in-depth look at the breathability of non-woven fabric to help you fully understand the advantages and applicable scenarios of this material.

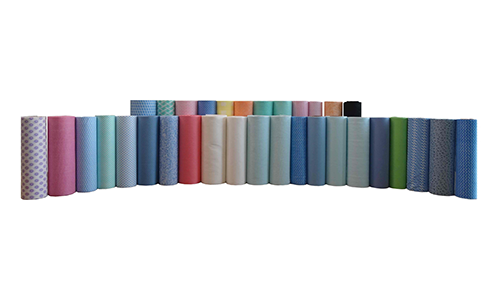

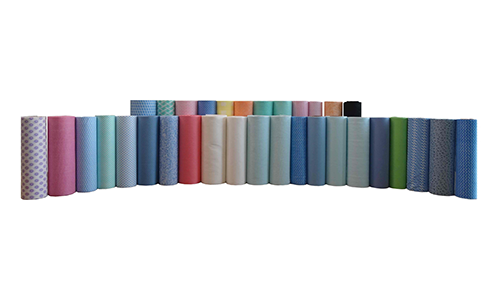

Non-woven fabric is a material created by physically, chemically, or mechanically bonding fibres into a fabric-like structure without traditional textile processes. The fibre arrangement structure of non-woven fabric differs from that of conventional textiles, offering characteristics such as lightweight, high strength, and low cost. Common materials include polyester, polypropylene (PP), and viscose fibres.

How breathable is non-woven fabric?

The breathability of non-woven fabric primarily depends on its fibre density and manufacturing process. Generally, spunlace non-woven fabric has better breathability due to larger gaps between fibres, while thermal bonding and composite non-woven fabrics have relatively lower breathability.

Breathability principle

Non-woven fabric contains numerous microscopic gaps between fibres, allowing air to flow freely through these gaps, thereby achieving breathability. The quality of breathability directly affects wearing comfort, filtration efficiency, and protective performance.

Specific manifestations of breathability

Medical masks: High-breathability non-woven fabric ensures smooth breathing while blocking bacteria.

Disposable protective clothing: It must balance liquid penetration resistance and good breathability to ensure wearer comfort.

Home cleaning products: Breathable non-woven fabric quickly absorbs moisture and wicks away sweat, improving cleaning efficiency.

How to assess the breathability of non-woven fabric?

Typically, a breathability tester is used for measurement, with the unit being L/m²/s (litres per square metre per second). Higher values indicate smoother airflow and better breathability. When selecting, balance breathability and protective performance requirements based on the application scenario.

Advantages of non-woven fabric breathability

Excellent comfort

Good breathability makes non-woven fabric products more comfortable to wear, reducing stuffiness.

Strong protective performance

High-quality non-woven fabric can also effectively block bacteria, dust, and liquids, combining breathability with protection.

Environmentally friendly and biodegradable

Many modern non-woven fabric products use biodegradable materials, making them both environmentally friendly and practical.

Conclusion: Is non-woven fabric breathable? The answer is yes, but the appropriate product should be selected based on type and application.

As a multifunctional material, the breathability of non-woven fabric varies depending on the type and manufacturing process. Understanding the breathability characteristics of non-woven fabric can help you make more informed decisions during procurement and use. If you are seeking a breathable and safe non-woven fabric product, it is recommended to choose a reputable supplier and pay attention to the breathability test data of the product.