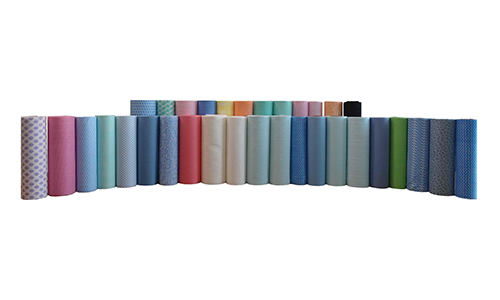

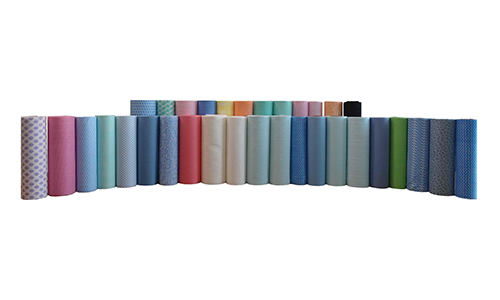

When selecting materials, many people wonder: which is better, non-woven fabric or non-woven cloth? While they may seem like two distinct materials, their relationship in practical applications is not a simple comparison but rather a concept worth exploring in depth within the industry. As a company with years of experience in non-woven cloth manufacturing, we will provide a detailed analysis to help you make more informed procurement decisions.

I. Concepts of Non-Woven Fabric and Non-Woven Fabric

As the name suggests, non-woven fabric is a type of fabric that is not spun or woven. It is formed by directly laying fibers and bonding them together (e.g., through hydroentanglement, thermal bonding, chemical bonding, etc.). It encompasses various types of materials, such as hydroentangled non-woven fabric, needle-punched non-woven fabric, and thermal-bonded non-woven fabric.

Nonwoven (Nonwoven)

‘Nonwoven’ is another term for ‘nonwoven fabric,’ and there is no difference in their definitions; they are simply different translations and industry conventions. In many international trade documents and raw material procurement orders, both terms are interchangeable.

II. Why is there a question of ‘which is better’?

The main reason is that different manufacturers and production processes can lead to variations in the tactile feel, strength, breathability, and absorbency of nonwoven fabrics/nonwoven textiles. Therefore, some people mistakenly believe these are two completely different products and attempt to distinguish between ‘good’ and ‘bad.’

III. Key factors influencing material quality

Raw materials

Viscose fibres: High absorbency, soft and skin-friendly

Polyester fibres: High strength, durable and wear-resistant

Wood pulp fibres: Biodegradable, excellent environmental performance

Processing

Spunlace process: Fibres are tightly intertwined, high softness, suitable for wet wipes and facial tissues

Thermal bonding process: Smooth surface, suitable for industrial packaging materials

Application matching

Different industries such as medical, hygiene, packaging, and home use have varying requirements for material performance. The best choice is the one that suits the application.

4. How to choose the right non-woven fabric/non-woven cloth for your needs?

Clarify the application: Is it for wet wipes, masks, disposable bed sheets, or industrial packaging?

Pay attention to grammage (GSM): Higher grammage fabrics are thicker, while lower grammage fabrics are lighter and more breathable.

Environmental friendliness and safety: Is it biodegradable? Has it passed FDA/ISO certifications?

5. Conclusion: Which is better? It depends on your needs.

From a definitional perspective, non-woven fabric and non-woven fabric are the same material; there is no such thing as one being ‘better’ than the other. The key to distinguishing between quality lies in the raw materials, production process, and intended use. For different industry applications, selecting the appropriate non-woven fabric specifications and production process is essential to achieving optimal performance and cost-effectiveness.