In industries such as healthcare, medical supplies, cleaning, personal care, and industrial manufacturing, nonwoven fabric procurement is critical for businesses. Selecting high-quality nonwoven suppliers and suitable materials ensures product performance, compliance with international standards, and fulfillment of application requirements. This article shares key factors to focus on when procuring high-quality nonwoven fabrics, helping enterprises make informed decisions.

1. Analysis of Nonwoven Material Composition and Properties

The base materials and production processes of nonwoven fabrics determine their performance characteristics. Different material combinations influence absorbency, strength, softness, and environmental attributes. Common types and their features are outlined below:

Material Type

|

Characteristics

|

Applications

|

Viscose/Polyester

|

Soft, durable, excellent absorbency

|

Wipes, personal care, sanitary products

|

Wood Pulp/Polyester

|

High strength, superior absorbency

|

Precision industrial, medical applications

|

Wood Pulp/Polypropylene (PP)

|

Durable, economical

|

Disposable cleaning cloths

|

Biodegradable Materials

|

Environmentally friendly, decomposable

|

Sustainable products for European and American markets

|

Flushable Materials

|

Rapid decomposition in water

|

Flushable wipes

|

Polypropylene (PP)/Meltblown

|

Lightweight, high strength, chemical resistance

|

Masks, Filtration, Industrial Cleaning

|

When procuring, select the most suitable material based on specific applications to ensure performance meets requirements.

2. High-Quality Nonwoven Fabric Certifications and International Standards

Global buyers increasingly prioritize materials compliant with international quality and safety standards. Key certifications include:

FSC / PEFC: Sustainable wood pulp sourcing

ISO 9001 / ISO 14001: Quality and environmental management

RoHS / MSDS: Chemical safety

EDANA, SGS Test Reports: Third-party performance verification

Certified materials not only meet export requirements but also help buyers pass customer audits smoothly, enhancing market credibility.

3. Reliable Nonwoven Suppliers and Production Capacity Assessment

High-quality nonwovens depend on stable supply. When sourcing, focus on:

Stable production capacity to fulfill large-volume orders

Stringent quality control to minimize batch variations

On-time delivery to meet peak season demands

Selecting suppliers with reliable manufacturing capabilities ensures uninterrupted business operations unaffected by raw material fluctuations.

4. Custom Nonwoven Fabric Selection Guide

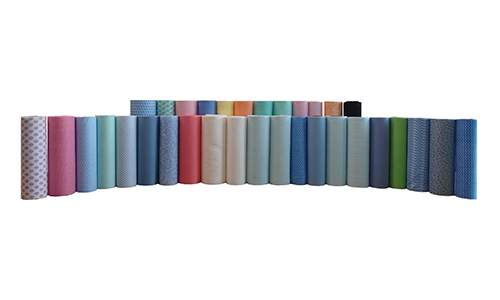

Modern industries increasingly demand personalized nonwoven solutions. Key customization options include:

- Grammage range

- Fabric surface patterns: plain weave, embossed, printed

- Roll width and sheet specifications

- Color options

Suppliers offering flexible customization empower B2B clients to develop differentiated products and enhance market competitiveness.

5. Nonwoven Fabric Selection by Application

Application

|

Material Requirements

|

Hygiene & Wipes

|

Soft, absorbent, low linting

|

Medical

|

Sterilizable, fully certified

|

Filtration Materials

|

High density, durable, chemical-resistant

|

Industrial Cleaning

|

High strength, reusable, abrasion-resistant

|

Understanding end-use ensures selected materials meet performance expectations.

FAQ (Frequently Asked Questions)

Q1: What defines high-quality nonwoven fabric?

A1: High-quality nonwoven fabric typically offers superior softness, absorbency, and strength while meeting international certification standards for hygiene, medical, cleaning, and industrial applications.

Q2: How to select a reliable nonwoven supplier?

A2: Choose suppliers with stable production capacity, stringent quality control, international certifications, and customization capabilities to ensure consistent supply and product performance.

Q3: What parameters can be customized for nonwoven fabrics?

A3: Basis weight, surface patterns, roll width, sheet specifications, and colors can all be customized to meet specific requirements.

Q4: Which certifications are most critical for exporting nonwoven fabrics?

A4: FSC/PEFC, ISO9001/14001, RoHS, MSDS, along with EDANA or SGS test reports, are particularly crucial for export compliance and customer audits.

Conclusion and Call to Action

When sourcing nonwoven fabrics, buyers should prioritize: material composition, certification credentials, supplier reliability, customization capabilities, and application requirements. Making informed decisions reduces procurement risks, enhances product performance, and supports long-term business growth.