A revolutionary material woven using high-pressure water jets is quietly reshaping the future landscape across industries from healthcare and automotive to agriculture.

In the field of

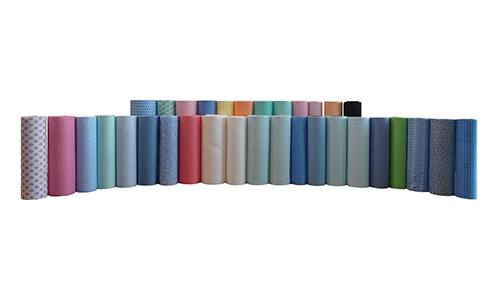

eco-friendly materials, a silent revolution is underway. Eco-friendly hydroentangled non-woven fabric—a new material created by intertwining fibre nets using high-pressure micro-water jets—is rapidly penetrating every aspect of our lives thanks to its unique eco-friendly properties and outstanding performance. From protective clothing for medical staff to soundproofing layers in car interiors, from high-end cosmetic cotton pads to agricultural mulch, the application scope of this material is expanding rapidly, creating one billion-dollar market opportunity after another.

I. Core Advantages of Spunlace Non-woven Fabrics

Environmentally Friendly and Biodegradable: No chemical adhesives are added throughout the production process, and the natural fibre material can be effectively decomposed in the natural environment, reducing ‘white pollution.’

Outstanding Physical Properties: High strength, strong moisture absorption, excellent breathability, combined with a soft touch and durable characteristics, perfectly balancing comfort and functionality.

Processing Flexibility: Can be processed into various shapes via thermal pressing and easily modified to incorporate special functions such as antibacterial, waterproof, and flame-retardant properties.

II. Performance Comparison Between Spunlace Nonwoven Fabrics and Traditional Textile Materials

Characteristic

|

Spunlace Nonwoven Fabric

|

Traditional Woven Fabric

|

Production Process

|

No chemical adhesives

|

Requires chemical treatment agents

|

Degradation Cycle

|

1-2 years (natural fibres)

|

20-30 years

|

Energy consumption in production

|

Low (spunlace process)

|

High (multiple processes)

|

Functional expandability

|

Easy to add antibacterial, waterproof, and other properties

|

Difficult to achieve multifunctional composites

|

III. Top Ten Disruptive Industry Application Scenarios

Spunlace nonwoven fabric has become the core material for medical masks, surgical gowns, and disinfectant dressings. Its high filtration efficiency (over 99%) combined with breathability and comfort addresses the issue of discomfort from prolonged wear, with global demand surging by 300% during the 2020 pandemic.

Spunlace nonwoven fabric is increasingly used in soundproofing cotton, interior base fabrics, and filters for high-end vehicle models. It not only effectively reduces noise by 3-5 decibels but also reduces vehicle weight through lightweight design, enhancing the range of electric vehicles.

Environmental Protection Filtration Systems

In industrial wastewater treatment and air purification, spunlace nonwoven filter materials demonstrate exceptional particle retention capabilities. Their fibre gaps can be precisely controlled at the micron level, making them the preferred material for PM2.5 filtration.

Agricultural Technology Revolution

As agricultural cover film, it maintains soil moisture while suppressing weeds and reducing pesticide usage. Experimental data shows that fields covered with spunlace fabric save up to 40% water and increase crop yields by 15%.

High-end Hygiene Products

Infant diapers, sanitary napkins, and makeup pads are increasingly adopting cotton spunlace fabric due to its skin-friendly, non-irritating properties. Market share is growing at an annual rate of 12%, making it the mainstream direction for industry upgrades.

Smart Home Materials

Innovative waterproof and stain-resistant sofa fabrics and wall coverings are beginning to use spunlace base fabrics, combining aesthetics with functionality while addressing the cleaning challenges of traditional fabrics.

Building Waterproofing Engineering

Roof waterproofing layers and basement moisture-proof membranes using spunlace non-woven fabrics have a lifespan over twice that of traditional materials, with construction efficiency improved by 50%.

Electronic component wiping cloths require dust-free and lint-free properties, and the zero-shedding characteristic of spunlace fabric fibres has made it the designated cleaning material for semiconductor factories.

Fashionable and Eco-friendly Packaging

Luxury handbag linings and packaging are beginning to adopt dyed spunlace fabric, whose biodegradable properties meet international brand ESG standards.

The latest flame-retardant reinforced spunlace fabric is used in spacecraft insulation layers, withstanding extreme temperature differences (-100°C to 300°C), outperforming traditional ceramic fibres.

IV.Technical Process Decoded: How Can Water ‘Weave’ Fabric?

The core technology of spunlace non-woven fabric lies in high-pressure water jet piercing technology:

Fibre opening: Cotton, polyester, or viscose fibres are finely opened and mixed

Web formation and layering: forming a uniform fibre web (can be multi-layered)

Spunlace entanglement: High-pressure water jets at 160–220 bar penetrate the fibre layers, causing physical entanglement of the fibres

Drying and shaping: Forms a stable structure without damaging the fibres

This process overcomes the limitations of traditional textile manufacturing, which requires spinning and weaving, achieving 100% raw material utilisation (zero waste) and reducing energy consumption by 40%.

V. Market Prospects and Data Insights

According to the latest industry report:

In 2022, the Chinese spunlace nonwoven fabric market reached 23.8 billion yuan, a year-on-year increase of 12%.

Annual production exceeded 990,000 tonnes, with the average price rising to 26,900 yuan per tonne.

Demand in the medical and personal care sectors grew by over 15%, making it the largest application market.

National policies strongly promote development: The ‘Guiding Opinions on the High-Quality Development of the Industrial Textiles Industry’ explicitly require that the numerical control rate of key processes reach 70% by 2025.

VI.Future Trends: Breakthroughs in Functionalisation and Intelligence

Composite Functional Materials

By adding bamboo charcoal fibres and silver ions, permanent antibacterial properties are achieved, reducing infection rates in medical dressings by 90%.

Biodegradable Revolution

Fibre-based spunlace fabrics have a natural degradation cycle shortened to six months.

Smart responsive fabrics

Temperature/pH-sensitive spunlace fabrics for smart bandages (automatic colour-changing indication for wound healing)

VII.Call to action: Upgrade to a scientific cleaning solution immediately

Choose SoonerCleaning for:

EU dual-certified flushable base material (FLUSHSOON® technology)