With the rapid development of the nonwoven industry, spunlace nonwoven fabric has become one of the most widely used materials in cleaning, medical, household, and beauty fields. Based on years of market experience and application feedback, spunlace nonwoven fabric in today’s market can mainly be divided into four categories: viscose polyester spunlace nonwoven fabric, polyester woodpulp spunlace nonwoven fabric, polypropylene woodpulp spunlace nonwoven fabric, and biodegradable spunlace nonwoven fabric. Each type has its unique advantages and application scenarios.

1. Viscose Polyester Spunlace Nonwoven Fabric

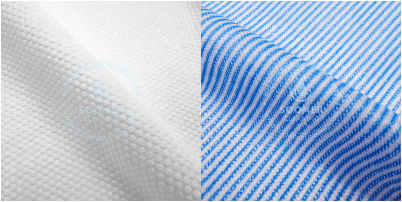

This type of spunlace nonwoven fabric is made from viscose and polyester fibers, with flexible blending ratios from 100% polyester to 100% viscose. It usually comes in 35–120gsm and can reach a maximum width of 3.2m. The fabric can be produced in multiple colors and patterns.

Key features include softness, skin-friendliness, high absorbency, low lint. Thanks to these properties, it is widely used in baby wipes, facial towels, bath towels, hair-drying towels.

Printed viscose polyester spunlace nonwoven fabric is especially popular in food and hospitality sectors, as it offers oil and water absorbency, and food-contact safety. Color-coded designs (red, yellow, blue, green) help reduce cross-contamination risks in kitchens, restaurants, hotels, and food processing.

Dyed viscose polyester spunlace nonwoven fabric is designed for medium-duty cleaning, with strong absorbency and durability. It performs well in both dry and wet conditions, supports multiple reuses, and meets SGS food-contact standards. It is widely applied in homes, supermarkets, restaurants, and fresh food packaging as absorbent pads

.

2. Polyester Woodpulp Spunlace Nonwoven Fabric

Polyester woodpulp spunlace nonwoven fabric combines the absorbency of woodpulp fibers with the strength of polyester. Standard weights range from 40–100gsm, with widths up to 3.2m.

-Plain type: cost-effective, strong tensile strength, low linting, suitable for cleaning laboratory instruments, electronic components, aerospace equipment, and workers’ hand wipes.

-Creped type: soft touch, scratch-free for glass and automotive surfaces, also used as medical hand towels.

-High-friction type: rough surface structure enhances dirt removal, making it effective for cleaning paint, glue, and uneven or hard-to-reach areas.

Special variants include:

-Printing machine wipes – designed with high absorbency, antistatic properties, softness, and low linting.

-Water-repellent surgical gown fabric – breathable, drapable, resistant to blood and alcohol, compliant with EN13795, and tested free of latex and PVC. It is a reliable protective material for medical staff.

3. Polypropylene Woodpulp Spunlace Nonwoven Fabric

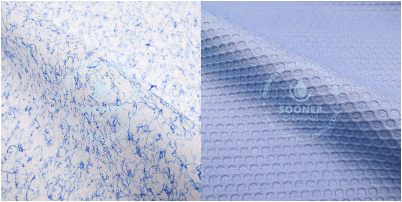

This spunlace nonwoven fabric is manufactured using a unique “two-step” process, combining soft woodpulp with high-strength polypropylene. It usually comes in 35–125gsm with a maximum width of 3.2m and can be processed into plain, embossed, or printed designs in multiple colors.

-Plain type: oil absorption, absorbent, tear-resistant, suitable for daily household and light industrial cleaning.

-Embossed type: enhanced wiping performance, ideal for heavy-duty cleaning, oil removal, machinery maintenance, and rough surface wiping.

-Printed type: reusable, fast absorbing, and commonly used in food processing, hotels, and fast-food restaurants.

-Blood-striped type: one side has colored thread for higher friction, while the other side is soft like cloth, Very suitable for heavy-stain cleaning, industrial bucket-type wet wipes, kitchen countertops, etc.

4. Biodegradable Spunlace Nonwoven Fabric

As sustainability becomes a global trend, biodegradable spunlace nonwoven fabric is gaining attention. It is made from eco-friendly fibers such as viscose, cotton, bamboo fiber, lyocell, and woodpulp, all of which are biodegradable.

This type of spunlace fabric is mainly used in wet wipes, facial masks, cleansing towels, and household wipes. With its eco-friendly nature, it aligns with the global call for sustainable and green development. In the future, biodegradable spunlace nonwoven fabric is expected to become one of the leading product directions in the industry.

Conclusion

As one of the fastest-growing categories in the nonwoven industry, spunlace nonwoven fabric has shown strong potential in industrial, medical, household, and beauty applications. From viscose polyester, polyester woodpulp, polypropylene woodpulp to biodegradable fabrics, each type serves different purposes with unique performance advantages. spunlace nonwoven fabric will continue to play a key role in diversified applications and eco-friendly product development.